Wood Engraving Services

We use top-of-the-line CO2 laser engraving machines to engrave and laser cut wood for various customers, including online retailers, business gift distributors, and catering suppliers.

Wood engraving is a speciality of ours, and we enjoy working with it on our Co2 lasers. We can engrave names, photos, and company logos onto a wide range of wooden items.

The key advantage of Co2 laser engraving is that it enables you to engrave intricate images and cut complex shapes without the need for costly tooling charges. This allows us to offer engraving services for wooden products at a relatively low cost.

All woods react differently to laser engraving which burns and penetrates the wood to reveal a natural burnt effect. The appearance of all the contrasting shades gives a stylish debossed impression.

Recent laser engraved wood projects:

Laser-cut plywood shapes produced for art and craft supplier

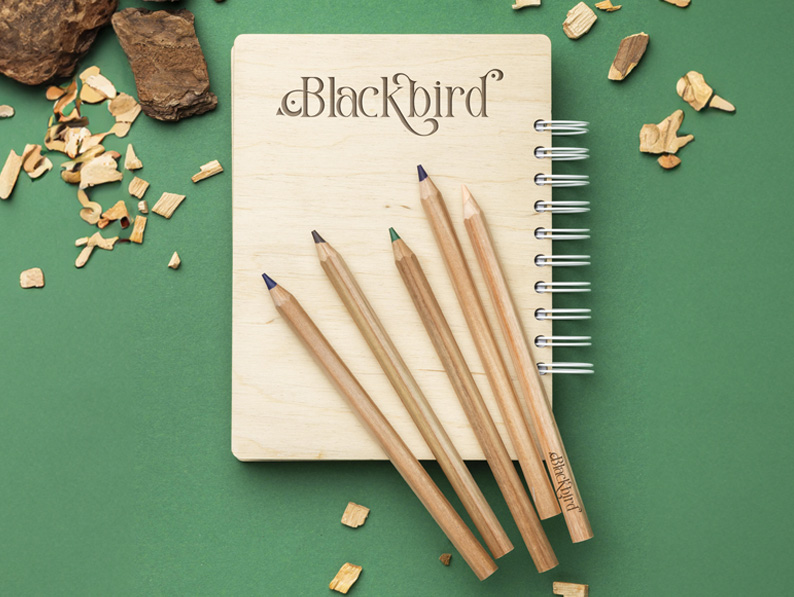

Wooden pens engraved with company logo for business gift distributor

Laser-engraved wooden boxes for e-commerce website

1000 wooden chopping boards engraved for catering products supplier

Some of the industries we supply:

Personalised Gift/Ecommerce

We work with online retailers and personalised gift suppliers to engrave and cut a wide range of personalised wooden products. We work with online sellers, large and small who sell their customised products on sites like Etsy, eBay and Not On The High Street.

Signs and Display

Many industries require bespoke wooden signage and laser-cut letters. We can help with both the design and cutting of these products.

Catering Supplies

We can work with artists and sculptures looking for a unique outcome using cut plastics. Even the most complex designs can be achieved using laser cutting technology and we would be delighted to discuss your specific requirements with you.

Business Gifts & Promotional Items

Since our inception, we have earned a strong reputation within the promotional gift industry as a reliable and trusted provider of engraving services. Our laser engraving capabilities allow us to engrave various wooden promotional and business gifts.

Choosing the right wood for laser engraving

If your primary material for laser engraving will be wood, there are a few important things to consider.

Resin Content

Wood typically burns lighter or darker, depending on the resin or sap content. If you require a darker mark, opt for wood that has high resin content like Cherry or Alder wood. If you’re looking for a lighter mark, choose a wood with a lower resin content.

Lighter wood provides a better contrast

Darker wood usually obscures the laser etching marks, making engraved photos or text difficult to see or recognise. Lighter wood, in contrast, provides a darker mark when engraved, giving you well-defined marks for optimal visibility.

The following wood types are easy to work with and produce excellent results:

If your primary material for laser engraving will be wood, there are a few important things to consider.

Soft woods

Woods such as balsa wood or poplar, require a lower laser power level and can be engraved and cut faster. Laser engraving produces a lighter contrast.

Hard woods

Woods such as oak or cherry are examples of dense woods. These woods require a higher laser power level for laser cutting and engraving. Engravings on hardwood exhibit greater contrast compared to those on softwood.

Veneers

Woods such as balsa wood or poplar, require a lower laser power level and can be engraved and cut faster. Laser engraving produces a lighter contrast.

MDF

This is an engineered wood-based sheet material made by bonding together wood fibres with a synthetic resin adhesive. The surface and edges are smooth and firm. So MDF can be easily engraved and cut. However, it should be noted that the cutting edges will become very dark during laser engraving and cutting.

Plywood

This consists of at least three layers of wood whose grain is glued and pressed at an angle of 90°. Plywood comes in different types of wood and is available in various thicknesses. The type of glue is important for laser processing, especially during laser cutting. Choose white-glued plywood panels or plywood panels made specifically for laser processing.

Frequently Asked Questions

Exotic Hardwoods: Harwood maple and dense hardwood is difficult to cut and produces inconsistent results when engraved.

Oleander & Mexican Elder: The fumes from engraving and cutting creates noxious fumes.

Fibreboard: Normally made of glued wood fibres which create noxious fumes, engraving quality is also poor.

Larch & Fir: Usually have a large number of uneven grains which are typically very hard. The surrounding wood (non-grained) is soft, and therefore the engraving is inconsistent.

Laser engraving wood typically removes small amounts of surface material with etching depths ranging from 0.1mm to 0.9mm depending on the wood type. Various depths can be achieved by altering the power and speed settings producing a layered effect.

If you have a specific requirement or need some technical advice, please speak to one of the sales team who will be happy to help. Contact Us

Ideally all artwork needs to be vectorised and supplied in either eps, ai, or Corel Draw cdr files with all text converted to curves. If you are unable to supply artwork in this format our design team can convert your design into the correct format. The cost to convert artworks is really dependant on the complexity of the design and the amount of re-drawing required. Simply send us your design or drawing and we will provide a quote to convert the artwork.

Request Quote

Fill out our quote form and we will get back to you with a quotation for your project.

Arrange Callback

Choose a time that suits you and our team will give you a call back to discuss your requirements.